Classic car upholstery restoration requires skills and techniques that differ from modern automotive interior work. Original interiors often feature materials and construction methods rarely used in contemporary vehicles, so it’s essential to understand the correct strategies for your project.

Proper restoration maintains authenticity while preserving vehicle value. This guide covers essential traditional upholstery methods for restoring classic car interiors.

Understanding Traditional Upholstery

Traditional upholstery uses natural materials and hand-stitching techniques that were standard in automotive manufacturing before 1980. These methods include horsehair padding, jute webbing, coil springs and hand-sewn pleats.

Original classic car interior upholstery featured cotton batting, burlap and genuine leather or vinyl coverings installed using specific patterns and techniques unique to each manufacturer.

Traditional methods offer distinct advantages for restoration work, including:

- Factory specifications: Original construction techniques create seat contours that match factory specifications.

- Material integrity: Hand-stitching produces durable seams that maintain their integrity over decades.

- Longevity: Natural materials allow better air circulation than synthetic alternatives, reducing moisture buildup and extending material life.

- Precise matching: Traditional techniques enable you to match original stitch patterns, pleat spacing and material grain direction precisely.

Essential tools and materials needed for traditional upholstery work include:

- Upholstery needles in various sizes

- Hog ring pliers for securing materials

- Spring stretchers for proper tensioning

- Webbing stretchers for tight installation

- Tack hammers for traditional fastening

- Curved needles for difficult angles

- Jute webbing for foundation support

- Hog rings, tacks and heavy upholstery for assembly

How to Restore Classic Car Upholstery

Classic car interior restoration projects require a methodical approach and attention to detail. Following the proper process helps you achieve professional results that match factory specifications. This process applies to bucket seats, bench seats and rear seat assemblies across all classic vehicle makes and models.

1. Preparation

Remove the seats from the vehicle using the proper socket sizes to avoid damaging mounting bolts. Before disassembly, photograph every angle and detail of the original construction, or take a video capturing every angle of the seat. These images will be crucial for reassembly. As you remove the old covering, treat each piece as a pattern for cutting raw material.

Once stripped to bare frames, inspect thoroughly for rust or structural damage that needs attention. Repair damage before proceeding, as frame issues will impact your finished upholstery. Clean frames thoroughly and apply rust prevention coating.

2. Building the Foundation

Using a webbing stretcher, install strips across the frame bottom with 2 to 3 inches spacing between them. This spacing provides optimal support without excess material. Secure webbing with tacks or clips, depending on frame design.

Following your reference photos, position coil springs on the webbing foundation. Tie springs using the eight-way hand tying method for proper support and movement. Cover the springs with burlap, pulling it tight and securing the edges to the frame.

The padding layer is the most crucial. Start with rubberized hair or traditional horsehair, building thickness gradually while shaping proper contours. Stitch through the burlap to anchor everything and shape cotton batting carefully as the final padding layer to eliminate irregularities. A muslin cover pulled tight over everything compresses the padding and creates your working surface.

3. Shaping and Stitching

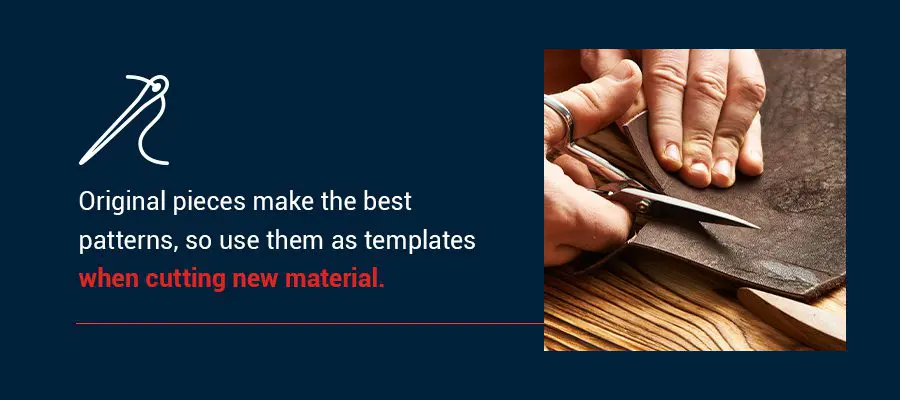

Original pieces make the best patterns, so use them as templates when cutting new material. Add extra inches for proper pulling and securing. For pleated designs typical in classic car interior restoration, mark stitch lines on the reverse side and calculate spacing. Most classics used 2- to 3-inch pleats, though some luxury models feature tighter spacing.

You’ll want to double-stitch pleat bases using heavy upholstery thread and appropriate needles since they endure the most stress. For seat edges, create listing wires using covered wire secured inside fabric channels. Starting at the center and working outward, install covering material, pulling it evenly to prevent wrinkles or bunching. Secure edges using hog rings or tacks.

Before assembly, attach piping or welting to seam edges, using matching or contrasting piping based on the original design. Install seat back covers using the same techniques, ensuring proper alignment with the seat bottom patterns. If button tufting was originally present, create it using proper spacing and pull-through technique.

4. Finishing Touches

Install finished seat assemblies into frames and verify proper fit. To test for successful reassembly, check for good spring action and appropriate padding compression. Add trim pieces, emblems or hardware removed during disassembly.

Install carpeting using bows and proper tensioning methods, ensuring all materials lay smooth without sagging or wrinkles.

Raybuck Auto Body Parts’ Upholstery Options for Classic Cars

Raybuck Auto Body Parts provides comprehensive interior restoration solutions for classic trucks and vehicles. With over 40 years of experience serving the restoration community, we stock complete upholstery lines for Chevy, Ford, Dodge and more from the 1940s through the 1990s.

Upholstery Kits

Our complete upholstery kits for classic cars and trucks contain the materials needed to reupholster classics. They include pre-sewn seat covers, door panels, and carpeting cut to exact specifications. The materials in our quality classic car upholstery kits match the original grain patterns and colors for authentic restoration.

Seat Covers

Raybuck Auto Body Parts offers seat covers for classic cars and trucks in multiple options to match your restoration needs. Standard covers use quality vinyl that matches original specifications for daily drivers and work trucks. Deluxe versions have upgraded materials, including leather options. All covers include proper stitching patterns, piping and listing wires for correct installation.

Individual Components

For selective restorative projects, Raybuck Auto Body Parts stocks individual interior parts. Pre-formed headliners feature proper bow pockets and sun visor cutouts for an exact fit. Door panels have correct grain patterns and mounting clip locations specific to each application.

Our carpet set options include jute backing and proper binding for extended life. Our selection of seat components includes springs, webbing, padding materials and complete hardware sets for frame-up restoration. All components meet original thickness and material specifications.

Tips and Tricks for Success

Small details make all the difference in getting professional results. Keep these strategies in mind as you work:

- Start with simple components like door panels before attempting seat assemblies.

- Document each step with photographs for future reference.

- Test fit all components before final installation.

- Practice stitching on scrap material to develop a consistent technique.

- Allow adhesives full cure time before stressing bonds.

- Use proper stretching tools rather than improvising.

- Match thread weight to material thickness.

- Mark all alignment points before removing old materials.

- Keep original parts as templates even if they’re damaged.

- Avoid low-quality materials.

Reupholster Your Classic Truck or Car With Raybuck Auto Body Parts

Traditional upholstery techniques produce authentic classic car interior upholstery restoration results. Using proper materials and time-tested methods helps you make repairs that match factory quality and last for decades.

Raybuck Auto Body Parts brings over 35 years of restoration expertise to your project. We offer complete upholstery solutions at competitive prices, and orders ship within one business day. Our knowledgeable staff works on classic vehicles and understands your restoration needs.

Shop upholstery kits for classic cars today, or contact us for expert restoration advice.