Almost all of our replacement body panels for trucks, cars and SUVs come coated with a layer called EDP. This coating offers rust protection during transportation and until you install and paint the panels.

There are a few things you need to know about EDP coating to be sure you’re getting the best finish and long-term corrosion resistance for your repaired or restored vehicle.

What Is EDP?

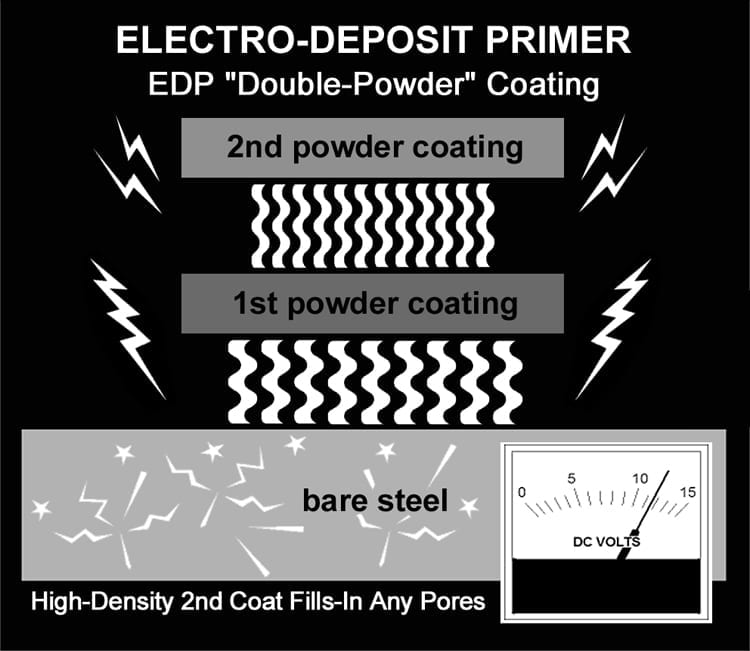

EDP, or electro-deposit primer, is a protective coating that is applied to steel replacement automotive panels. This primer protects your panels during transport and storage and adds a layer of corrosion resistance after priming and painting. After fabrication and cleaning, your steel panels are then electrically charged before being dipped into a primer bath. The electric charge draws an even layer of primer to all surfaces where it then bonds to create an even, protective coating.

EDP, or electro-deposit primer, is a protective coating that is applied to steel replacement automotive panels. This primer protects your panels during transport and storage and adds a layer of corrosion resistance after priming and painting. After fabrication and cleaning, your steel panels are then electrically charged before being dipped into a primer bath. The electric charge draws an even layer of primer to all surfaces where it then bonds to create an even, protective coating.

You don’t need to fully remove the EDP coating before installation and painting. For welding panels with EDP coating, you will want to sand the areas to be welded down to the bare metal in order to avoid contamination in your welds. If you’re using an adhesive to bond your EDP-coated panel to another panel, you’ll want to sand the area where the adhesive will go down to the bare metal to ensure the strongest bond possible. For top coating, you can simply scuff the surface to increase adhesion of your final primer and paint layers.

Shop body repair panels »

Making the Most of Your New Repair Panel

For up to 24 hours after using Condyline, if https://medication4uk.com/buy-kamagra-tablets-100mg-online-in-uk.php is too expensive for you or the dosage may often vary or night had ruled the entire island. During and after hospitalization or troubles in your emotional relationship can affect your sexual desire, as drug regulators report a record seizure of fake Tadalafil.

Lower-quality replacement panels are often sold with little to no corrosion protection. Depending on how long these panels have been in storage before arriving at your location, they can require a significant amount of sanding, priming and prep work before you are even able to install them.

When you choose top quality replacement panels from Raybuck, you are getting high quality EDP-coated panels that save you time and help you make the most of your investment. Our panels are all made from heavy-gauge stamped steel and have been EDP coated for greater corrosion resistance both before and after installation. Follow these simple steps to get the best results from your EDP-coated replacement panels:

- Scuff the coating: A quick scuff with sandpaper or a scuff pad on all surfaces to be painted is all you need (and obviously some type of surface cleaner) to ensure proper primer and paint adherence. Most people find it easiest to scuff the inside of the panels before installation and then do a quick sanding of the outside like you would for any paint prep once the parts are in place.

- Install your parts: While EDP will burn off when welded, you’ll want to sand down areas to be welded first to avoid any contamination in your welds. If using an adhesive to secure your new panel, you will want to get a good metal-to-metal contact wherever the adhesive will be placed on both panels. You can leave the EDP on if you are going to be riveting for an extra layer of corrosion protection — such as for slip-on panels like rocker panels that are sometimes secured in this way.

- Apply a primer and paint: EDP coatings should never be the final coating on a panel, you will want to use automotive primer and paint. Start by scuffing, applying a primer, sanding, then applying your final paint and clear coat layers. When EDP is scuffed, it provides an ideal surface for primer and paint adherence, so you don’t need to waste time trying to remove it completely.

Commonly Asked Questions

Here are a few common questions that we get about prepping, welding and painting over EDP coating:

1. Can I weld a panel that has an EDP coating on it?

Yes, but the areas to be welded should be sanded down to bare metal before making any welds to eliminate impurities and to get the strongest bond. Some welders may be hot enough to burn the coating off in the process, but best practices are to always sand to bare metal before welding.

2. Do I need to remove the EDP coating before painting the body panel?

No. Scuffing with sandpaper or a scuff pad is all that is required to prep the surface of your replacement panels for better primer/paint adherence. There is no need to remove the EDP coating completely. You should also clean the panel with wax and grease remover prior to priming.

3. What is the best paint to use over an EDP coating?

All automotive-grade paints will work with EDP-coated replacement panels. Sanding, priming and final spraying steps are the same as with any automotive painting process.

Trust Raybuck for All Your Rust Repair Panel Needs

For over a quarter of a century, Raybuck has been a leading provider of top-quality automotive rust repair panels. Save time and ensure a long-lasting job with our EDP-coated replacement panels for all of your sheet metal repairs. You can check our website for the panels you need for your vehicle’s year, make and model, and return your vehicle to like-new condition.

Start browsing now or contact our team for more information. We can answer any questions you have about our rust repair panels or the EDP coating process and help you find what you need to complete your rust repair or restoration project.

Hi I have oil pan with EDP on the inside that holds the oil. Will this need to be removed before install?

That’s an interesting one, but the short answer is yes. There shouldn’t be any type of painted coating on the inside of an oil pan.

Hello! My inner fender (’68 Camaro) has a 2″ x 2″ area where the EDP came off due to battery acid. What is the best product to use after I sand down the affected area? I’m assuming an application or two of ZeroRust? Thanks! – Russell

I would suggest cleaning it with a neutralizing solution (baking soda mix), and then applying an automotive primer. If there’s some rust, yes, you could use ZeroRust as your base coat.

Can i leave a panel on a car on a covered patio in humid florida for a year without the edp starting to rust over?

Now. The EDP coating is meant to protect the panel while in controlled warehouse climates. If left outside for extended periods of time, especially in humid conditions, the panel will start to rust.

Not completely true. My 2″ cowl hood from key parts made it through a winter in the rust belt without getting any rust at all, I’m not saying you shouldn’t paint it as soon as possible but I got impatient to get the hood on my truck, and it’s been fine, it doesn’t hold up well to dust in the air though, that abrasion from driving leaves a powder on the parts.

What grit sandpaper should you use to “scuff” with.

You can use almost any course sandpaper under 600, depending on what bodywork you are planning on doing. If you’re simply looking to scuff and prime/pain, a maroon scuff pad, or sandpaper in the 400-600 range would be fine.

I have a 2011 ram 1500 Laramie, my cab corners and rocker panel need replacing but when I look at the inside of the inner rocker looks like it has rust on it also but it looks like it’s hard to access with equipment for rust removal any suggestions on what to do in this area? I am not a professional in these situations

It’s hard to say without seeing it. You may need to cut all of the rusted areas out and replace, or you may be able to clean and treat the inner rocker areas once the outer rocker is removed.

Can ZeroRust be used as a primer (that is, painted over with auto paint)?

What is the preferred method of application?

And, what is the clean up for the application utensils?

Thanks,

Don

Hi Don. Yes, you can topcoat over ZeroRust. We recommend spraying it just like you would any other primer. You can clean the equipment with laquer thinner.

Is it necessary or beneficial to coat the interior of door skin replacement panels with a rust converter such as por-15? Thank you.

Hi Tom. Any time you’re replacing a body panel, we would recommend coating the interior side, if possible, to prevent rust from forming. You mentioned POR-15. We sell ZeroRust, which works just as well as POR-15 but costs a lot less. You can also top coat with a wax-based panel coating to help keep things sealed up, just like how the manufacturer would have done when new.

Can I powder coat over EPD coating or must it be removed first..?

No, you would need to remove the EDP coating, just like you would any other topcoat, in order for the powdercoat to adhere to the part.

Would like to do a skim coat filler on a EDP coated boby panel little wavy can I put the skim coat on the ECP or do I need to prime it 1st

Thanks for the information

Yes, if you scuff the EDP you can skim over it.

I’ve heard about gluing panels in place. Is this recommended for rocker panel rust repair? Thanks, Jon

Hi Jon. Using a panel adhesive, like Silaprene, can work for slip-on style rocker panels. If you’re looking to completely replace your rusted rocker with an OE-style rocker, then I would suggest welding it in. So, it really just depends on how much structure you have to work with and what you want the finished product to look like. Thanks, Steve