Rocker panels are critical to your vehicle’s exterior, offering structural reinforcements as a barrier against road debris, moisture and salt. With quality rocker panels installed, you can help protect your vehicle from rust or potential damage if you’re in an accident.

When it’s time to replace your rocker panels, you must decide on original equipment manufacturer (OEM) or aftermarket options. The right rocker panel depends on your budget and vehicle. Ensure you understand the differences between OEM vs. aftermarket rocker panels before making your next purchase.

OEM Rocker Panels

OEM rocker panels come directly from the vehicle’s manufacturer. They’re produced by the manufacturer who made your vehicle or an approved supplier. OEM rocker panels are identical to the originals since the manufacturer has the exact specifications and materials needed for your car.

Advantages of OEM Rocker Panels

OEM rocker panels can be a quality option for vehicle owners. They offer you:

- Exact fit: OEM parts are designed specifically for the vehicle. You’re guaranteed to get rocker panels designed for your make and model without any modifications.

- Original specifications: OEM parts use the same materials, coatings and gauge thickness as the original panel.

- Warranty protection: Your warranty or insurance claim might require OEM replacement parts to maintain coverage.

Disadvantages of OEM Rocker Panels

While OEM rocker panels can be a good option for your vehicle, they’re not always the best choice. Some of the downsides of OEM rocker panels include:

- Higher cost: Since OEM components come from the manufacturer, they’re more expensive than aftermarket alternatives. They may also come as part of a larger section, which may cost even more and may require more prep and installation time.

- Limited availability: When vehicles are old or discontinued, finding OEM part replacements can be challenging.

- Professional Installation: OEM rocker panels may need professional installation and welding to ensure proper repairs and warranty coverage.

When to Choose OEM Parts

Choose OEM rocker panels when warranties and 100% precision matter the most. If your vehicle is under warranty, you might have to use OEM parts to maintain coverage. They’re also popular for classic restorations, where every detail must meet the original factory specifications. However, if you have a hard-to-match vehicle or don’t need the rocker panels to be an original match, aftermarket panels can work well.

Aftermarket Rocker Panels

Aftermarket rocker panels are replacement parts manufactured by third-party groups. They aren’t from the manufacturer. Instead, aftermarket parts are produced by manufacturers who make parts for a wide range of vehicles. This setup gives you more flexibility with pricing and availability. Aftermarket rocker panels come as direct-fit replacements and modified options. They’re great for anyone interested in well-fitting, affordable replacement rocker panels.

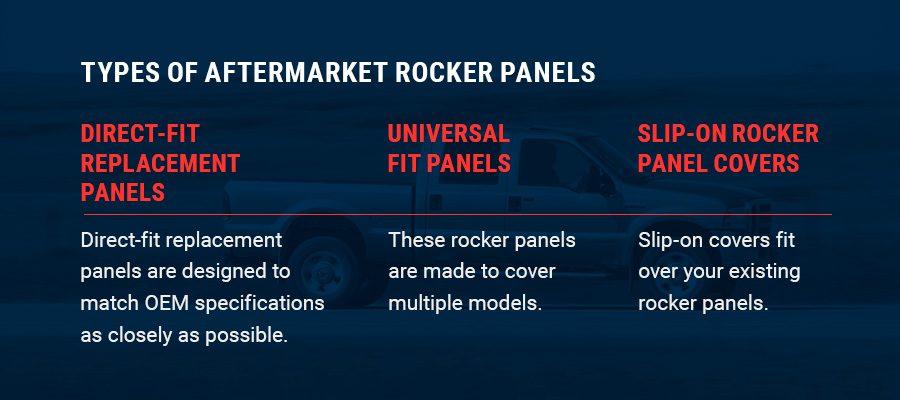

Types of Aftermarket Rocker Panels

There are several types of aftermarket rocker panels to choose from, including:

- Direct-fit replacement panels: Direct-fit replacement panels are designed to match OEM specifications as closely as possible. They fit the exact dimensions while costing less than OEM parts. There might be slight adjustments needed during installation, but the panels will fit your vehicle.

- Universal fit panels: These rocker panels are made to cover multiple models. They’re designed to fit a wider range of vehicles and are often made of thinner materials, so they often need bending, cutting or trimming to fit your vehicle. Universal fit options are more versatile than direct-fit replacements but usually need extra work during installation.

- Slip-on rocker panel covers: Slip-on covers fit over your existing rocker panels. They hide rust and damage without requiring a complete replacement. Choose slip-on rocker panel covers for lower-cost cosmetic fixes.

Advantages of Aftermarket Panels

The main advantage of aftermarket panels is cost. Since they’re made by a third party, they’re much more affordable and available than OEM parts. There’s also a wider selection of aftermarket rocker panels — you can invest in highly durable options made from thicker steel or corrosion-resistant materials for added durability. Additionally, the original manufacturer may not carry the rocker panel, forcing you to purchase the entire structure for replacements. Aftermarket panels are a great solution for vehicle owners who want a quality replacement without the high cost of OEM parts.

Disadvantages of Aftermarket Panels

Aftermarket rocker panels offer excellent affordability and variety. However, they do have a few potential drawbacks to consider:

- Potential fit issues: Aftermarket panels may not always match the OEM fit and finish, depending on the brand. Your rocker panels might fit closely but not as precisely as the OEM panels.

- Fit requirements: Needing adjustments to make the rocker panels fit exactly is common. Whether you purchase universal fit or direct-fit rocker panels, you might need to adjust them during installation.

- Quality variations: Aftermarket panel quality will depend on the manufacturer. Ensure you’re working with a seller who partners with reputable manufacturers to get a durable, seamless fit for your vehicle.

Installation Considerations for Rocker Panels

If you have no welding experience, a professional can install the rocker panels. If you’re doing the installation yourself, you must prepare carefully. At a minimum, expect to use these tools:

- Angle grinder

- Welder (unless using slip-on covers)

- Clamps

- Drill

- Spot weld cutter

- Body hammer

- Dolly set

Remove the old panels and clean the exposed areas. Make sure the panel is aligned properly before bolting it in place. Whether you’re welding or installing a slip-cover rocker panel, avoid gaps and misalignment. The panel must fit tightly to ensure solid structural support. Use a seam sealer to block moisture from getting inside, and always paint over the rocker panel to protect the car against corrosion.

How to Keep Rocker Panels in Top Condition

Once you’ve installed your rocker panels, you need to maintain them. Ensure you’re regularly inspecting and cleaning vehicle components to prevent wear. If you live in areas with lots of road salt, mud or debris, they might need more frequent cleanings. Wash your vehicle regularly, especially in the winter, to prevent buildup from accelerating wear.

If you see rust holes in your rocker panels, you should replace them. You can repair them yourself — just use spray foam and bondo to fill in the hole. Then, sand the area and paint. While patching can help, you need to address the cause of the rust or replace the panel completely for a lasting fix.

Additionally, if you find cracks or dents in the rocker panel, consider replacing it. Minor damage is easily covered with paint, but structural issues need welding or replacement to maintain panel integrity.

Find the Right Rocker Panels for Your Vehicle at Raybuck Auto Body Parts

Choosing high-quality parts makes all the difference when it’s time to replace your rocker panels. When you need durable aftermarket restoration parts, turn to the experts at Raybuck Auto Body Parts for assistance. Our rocker panels are built for strength and fit without the high dealership price tag. We specialize in providing reliable replacement parts for a wide range of vehicles.

Browse our selection today and get the quality parts you need to repair your ride!