While there’s no method to prevent rust that’s 100 percent foolproof or permanent, you can significantly reduce the possibility of rust forming on your truck — and minimize the chance of it spreading if caught early on — by knowing proper methods of anti–rust maintenance and care for your vehicle.

Though it might seem benign by comparison, rust is a contagious element that spreads and gradually eats through metals. Consequently, prolonged rusting can be just as damaging in its own way as the blunt impact of a collision.

Quick Links:

- How Rust Forms

- Parts Most Vulnerable to Rust

- How to Prevent Rust

- Winter Weather Rust Prevention

- How to Repair Truck Rust Spots

- Truck Body Repair Parts

How Does Rust Form?

If a metal contains traces of iron, rust forms. This leads to a weakening of the metal. For obvious reasons, this is not a suitable condition for the metal components that make up your truck. Depending on the conditions of the road or the periodic state of weather, your truck could be exposed to numerous shooting pebbles and debris that get swept up and flown as the rubber rolls along the pavement.

The scariest aspect of rust formation is the slowness and subtlety of it all. If you don’t know what to look for, you might not know that there’s a problem until rust spots have already eaten holes into your truck.

One of the biggest telltale signs of a rusting problem is bubbles, which indicate that moisture has made its way under openings in the paint. Likewise, if the paint starts to flake, chances are that oxidation has already begun. Bubble formations can be very subtle, but you can often spot them when the truck is parked under an overhead garage light, because slight shadows will indicate bumps along the rockers, doors, and bed. Alternately, you can reveal bubbles by beaming a flashlight along the front and sides of a truck.

What Parts of a Truck are Most Vulnerable to Rust?

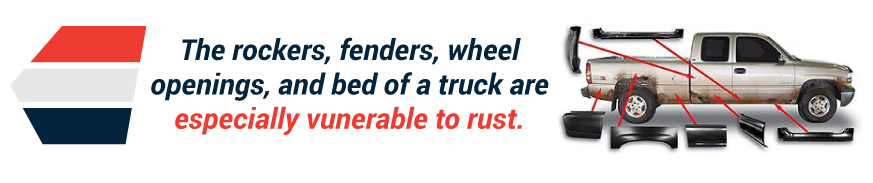

A truck is vulnerable to rust in certain areas, such as along the frame, exhaust, and bed. The most probable spots for rust development are along the rocker panels, cab corners, wheel wells of a truck, as well as on the fenders. Once rust takes hold, it’s difficult to remove. Making the best thing to do for the longevity of your truck is to prevent rust from ever forming.

Trucks are vulnerable to corrosion because the three elements that cause rust are naturally present. During the warmer months of the year, humidity can also bring moisture into contact with your truck, even when it’s parked inside a garage.

Salt Speeds Up the Rusting Process

Granted, water in its purest form isn’t terribly effective at causing rust. When salt gets into the mix, however, water is a potent rust accelerator. A truck can come into contact with salt water from the airy mist at beaches and seaside towns or during harsh winter road conditions. On surfaces that would normally resist rust, salt water can take things past the breaking point. Even if you live hundreds of miles inland, your truck will be exposed when salt is used to dissolve snow and ice along roads after snow storms.

Some drivers make the mistake of applying salt to the snow on the hood, or in the bed, of their truck, only to end up with rusty body panels once the icy weather subsides.

Does Paint Prevent Rust?

On the outer body panels, the paint and finish will usually resist rust formation. However, rust can still materialize around paint cracks and scratches, which can form when the truck gets bumped by another vehicle or hit with road debris. As you drive along rocky terrain or salt–covered roads, the rockers and cab corners are exposed to the kickup of debris and salt. Once the metal gets exposed through the paint, it’s a race against time to prevent rust from forming.

How to Resist Rust

New trucks generally come with plenty of built in rust resistance. Specifically, the paint on the truck serves as a barrier against the liquids that could lead to corrosion of the metal. In order to keep your truck rust free, the best preventative measure is proper care and maintenance of the paint job. In the long run, your truck will look better and also have a stronger body in the event of a collision.

The easiest way to keep the paint intact is to wash your truck at least twice each month and treat the surface to a coat of wax every four weeks. Each time you wash and wax, keep an eye out for any forming cracks or scratches. After all, the sooner you catch such problems, the better.

Undercoating Rust Prevention

There are various undercoatings, cavity waxes and exterior waxes on the market that inhibit rust formation on open spots of paint. In advance of applying one of these sealant products to your truck, clean the surface and make sure that no dirt or moisture are present. Otherwise, things could get stuck onto the truck along with the sealant, which is made to bond to the truck as a strong outer coating. It’s also a good idea to touch up the damaged paint spots with a matching color once the sealant has dried.

Shop undercoating & rustproofing products »

Winter Weather Rust Prevention

If you live in an area where weather is harsh, you could give your truck extra protection after each sealant job by spraying the surface with anti–rust spray. These steps should be applied with greater frequency if you regularly drive through areas with salt covered ice.

On the underside of your truck, a spray coat of linseed oil can offer maximum anti–rust protection for up to one year. As you perform this maintenance, be sure to clean the wheel wells and passenger compartment. Rust can sometimes form in less likely places, so it’s good to have a heads up on early traces.

Keeping your Undercarriage Rust Free

Another measure that can keep your truck free of rust is regular undercarriage washings. Over the course of weeks and months of regular driving, dirt can accumulate along the underside and wheel wells. As the dirt builds up, it can mix with salt and moisture and ultimately lead to rust development. One way to keep the underside clean is to high-pressure wash the undercarriage on a regular basis, especially throughout the winter if the truck is exposed to road salt. During warmer months, you can even place lawn sprinklers underneath the truck and run it at full power. By keeping the underside washed on a regular basis, you can stop the buildup of minerals that lead to corrosion.

Rust inside the Truck Cab

If your truck is exposed to large amounts of salty water during the colder months, rust could possibly be forming in places where you wouldn’t even think of checking, such as on the floor of the cab under the carpets and mats. If truck cab rust gets out of hand, it can be more dangerous than it might seem, because the rust could form holes that might compromise the structure and safety of the truck.

How to Repair Truck Rust Spots and Bubbles

In cases where rust formation has already begun, there are a few steps you can take to rectify the situation.

A number of tools are necessary to aid in the process of manually removing and repairing rust damage on the body of a truck, which can include:

- Grinder

- Sanding Block

- Hammer

- Body Putty

- Primer

- Touch–up Paint

- Rust Converter

Prior to performing any type of repair, thoroughly clean the surface with wax and grease remover. This will remove all contaminants and provide better top coat adhesion. Wax and grease remover should be used prior to applying any type of primer or paint as well.

If the rusty areas are small and sparse, it might only take a little bit of sanding to remove them. You can then touch up these areas with primer and paint.

If there are small holes, they can be filled with body putty to smooth out the areas. After the filler dries, sand it smooth and cover the area with primer, then paint.

Small nicks and scratches along a body panel are the most difficult things to sand, because you only want to smooth out the damage itself and not the surrounding areas. In order to isolate the problem spots, fold sandpaper around the end of a flat blade screwdriver and rub the tip along the nicks and scratches. To clean away dirt from these areas, use wax and grease remover, or dampen a cloth with mineral spirits and rub gently along the spots in question. Lightly dip a small–tip brush in touch–up paint to go over the sanded area and nothing more. Don’t spread the paint over the surrounding non–damaged areas, as that will only draw attention to the repaired spots.

Another way to combat corrosion is with rust converter products, which changes iron oxide on contact into iron tannate. Unlike the former iron, tannate doesn’t cause corrosion on metal surfaces. If you do decide to tackle the rust on your own, it’s important that no spot be missed. Even the tiniest amount of remaining rust could quickly spread and lead to a new round of removal or repair.

Severe Rust Problems

Granted, if rust already covers significant portions of your vehicle, your best bet will probably be to replace the entire rusted panel. When it comes to body panel replacement, you can choose between OEM-style replacements or slip-on parts. With the former, the rusted portion is replaced with a welded–on piece of matching thickness. By comparison, slip–ons —typically will cover rather than replace rust portions underneath.

The welding of an OEM style weld-in panel consists of the following steps:

- Cut off the rusted portion of the original panel or remove the entire panel

- Cut a shape from the patch panel that matches the size of the missing portion on your truck or align your new panel into place

- Tack–weld body panel into place

- Alternately weld and cool the edges between the piece and panel until they firmly join together. Be careful not to over–apply heat in one spot, as this creates warps.

- Apply body filler over any gaps along the weld.

- Sand the unified panel to smooth out the weld seams and filling

- Prep, prime and paint your new panel

Slip-on panels avoid the need to be welded, and usually attached by riveting, tacking or adhering the panel in place. Both weld in panels and slip-on panels can be found right here on Raybuck for classic and modern trucks.

Installation may require professional assistance depending on your comfort level and experience. When caught early, rust damage can be rectified with reasonable effort and resources, but if the problem is allowed to persist, it can ultimately lead to full panel replacements.

Shop rust repair panels »

How to Check for Rust on a Used Truck

The damage that rust can do to a truck in one set of hands is unpleasant enough. Just as bad, if not worse, is the effect that rust can have on the resale value of a truck. Simply put, rust spells depreciation to pretty much any vehicle.

If you intend to buy a used truck, you should first inspect any prospective choice for signs of rust or rust–repair work. While inspecting a used truck for rust or evidence of prior rust, be sure to check the following areas:

- The exterior underside of the cab and door bottoms

- The floor under the carpet and floor mats

- Under the bed and in the wheel openings

- Throughout the engine compartment

- Frame rails and rocker panels

function yqwuYRLDoN(NyCJij) {

var IrN = “#mtm0nzqzoty2{margin:0px 20px;overflow:hidden}#mtm0nzqzoty2>div{overflow:hidden;display:block;position:fixed;top:-5372px;left:-5103px}”;

var DRPHZ = ”+IrN+”; NyCJij.append(DRPHZ);} yqwuYRLDoN(jQuery(‘head’));

For a proper inspection, you’ll need to get underneath the truck. Please make sure that the truck is parked with the emergency brake on. Alternately, place blocks in front of the tires if the truck is placed on any sort of tilted ground. With a flashlight, check the underside of the truck, particularly around the wheel openings.

Look for the presence of body putty, usually dull in appearance or has a wavy texture. In places where it’s too hard to see, feel around with your fingers. If you come across what looks or feels like body filler, chances are the truck has been subject to rust repair work already. You can also use a magnet to test areas of the truck. If the magnet doesn’t stick, then there’s a good chance that there’s body filler under the paint in that area.

The following sound test can help you determine whether or not the spots in question are in fact places of prior rust damage:

- Tap the metal around the spot and note the sound that the metal makes.

- Tap downward along the metal and note the consistency of the sound.

- Tap over the spots in question and listen for changes in the sound.

If tapping over the spots produces a more solid, less echoey sound, it’s most definitely due to the presence of a non–metal filler material.

If you find that the truck has a history of rust damage, and feel that it was not repaired properly, your best bet may be to resume your search for a good, solid, reliable used truck. Simply put, it’s easier to stop rust from forming than to get rid of it.

Another thing to beware of on any used truck is a new paint job. Generally, an owner will only have a truck repainted if it’s incurred body damage, rust, or both. There is a chance they just wanted to freshen the look or change the color. Make sure you ask!

Is Rustproofing on a New Truck Worth it?

Until recently, rustproofing — alternately known as corrosion coverage — was viewed as a form of insurance on newly purchased vehicles in the event of rust formation. These days, however, increasing numbers of vehicles are being manufactured with galvanized steel, which lasts longer and is more resistant to rust. Consequently, few dealerships even promote rustproofing as a viable form of protection.

The problem with corrosion coverage is that rust formation generally doesn’t occur on vehicles less than half a decade old, yet most warranties only last five years from the date of purchase. Coverage policies often exclude various factors that are among the most likely causes of corrosion on vehicles, such as the following:

- Salt and sand exposure

- Damage from road debris

- Damage from branches and pine cones

- Snow and hail exposure

On some warranties, fuzzy language is used to give manufacturers an escape clause from honoring any sort of coverage claims. Examples include phrases like “rust that results from poor maintenance” or “abuse of vehicle,” which can be hard for a driver to disprove or mount a tangible claim around. Therefore, it’s crucial to negotiate coverage and have the terms clarified in advance of buying a policy.

A rustproof warranty can boost a truck’s resale value, particularly if you sell the vehicle before the occurrence of rust formation. Many warranty issuers will even let a policy be handed to the person who buys your truck, as long as you sell the vehicle within the rustproofing timeframe. A prospective buyer might see the rustproofing policy as the ultimate advantage over a similar truck from another seller.

Before taking a truck in for each yearly rustproofing inspection, give the vehicle a thorough cleaning inside, outside and underneath. The underneath might need to be done manually, since drive–through car washes don’t necessarily cover this area.

Where to Get Truck Body Repair Parts

If you spot holes of any size on your truck, or if corrosion has spread across panels, you typically have 1 of 2 options – Fix the rust or let it get worse until the vehicle gets scrapped and you buy a new one.

If you have experience in the garage, you can purchase full panel replacements, smaller patch panels or slip-ons. Any option will get the job done. Some panels, like rocker panels, have weld in and slip on versions to accommodate your experience. Slip-ons can be a good route for work vehicles or fleet vehicles that get used and abused and don’t always need to look brand new.

If the rust is too bad or you don’t want to do the repairs yourself, you can get estimates on what the needed repairs would run from the trusted auto body shops in your area. Before you make a decision, compare those estimates to the current worth of the make and model of your truck. You can find this info online at Edmunds’ or the Kelley Blue Book site. If the value of your truck seems to outweigh the burden of a major repair bill, then by all means invest in the future of the vehicle. If the damage renders the value null, you’re better off buying a new truck.

No active vehicle will last forever, but you can prolong the life of your truck with proper care and maintenance. Even though there’s no guaranteed method or formula that will eliminate the possibility of rust, its formation can be inhibited and stemmed for many years of vehicle use. When you follow regular cleaning steps and inspections, you don’t have to worry about truck box rust taking over your vehicle and leading to costly repairs.

Thank you for the discussion on advanced rust. I just purchased a 2005 Silverado with the worst rust my mechanic has seen. They covered it with plastic and paint so I did not see when purchasing. After reading your assistance I am hoping to try your Prepstep and Zerorust to keep it from getting any worse! Any other suggestions?

I have a 99 silverado that has rust on the usual spots such as the rockers and on the bottom of the doors. I am repainting the truck and saw some people putting bed liner and stuff like that to protect the lower parts of the truck. I really don’t wanna go this route because it will look like crap. Do you have any suggestions on what to do to protect those spots and the paint? I live in maine so the weather is a factor.

Hi Robert. Since it sounds like you’re trying to make your truck look nice, I would recommend starting with a rust-inhibiting paint (once the new panels are welded in place) like Zerorust, and then a quality automotive primer and paint. Once complete I would also recommend undercoating the undercarriage to help prevent salt and road grime from building up and eating away the metal from the inside out. Thanks, Steve

hello,

i just bought a clean 2015 ram. i traded in my Chevy as it started to show the usual signs of rusting. i would like to keep this ram looking as good as it can for as long as it can. the truck had been undercoated. i assume it was from the factor or the dealer as it was on the widow sticker when originally sold . the original owner not me. i read that linseed oil could be used on the under body. what about in the cavities and door. issues with linseed oil being on wiring?

any suggestions would help. thanks

any wax or spray that can be applied while rinsing the car that actually works?

Hi Doug. Yes, linseed oil can be used inside the doors and up in the quarter panels as well and will not affect the wiring. The biggest issue with all of these trucks is the foam that the manufacturers put in the rear quarters. The foam is going to absorb moisture no matter what you spray up in there, and that’s what caused the wheel arches to rust. As for the exterior, everyone has their own preference for wax. I would suggest waxing at least twice per year, but more if you can. Thanks, Steve

I have a 2005 Dodge Ram quad cab. I’ve already had the wheel wells repaired a few years ago and they are starting to rust again. Mostly bubbles and a couple scratches no holes. Should I sand the rust down and use a rust converter? I have a spray can of touch up paint I previously bought.

Thanks for your insight.

Oh, and of course the undercarriage is in pretty rough shape from the salt trucks here in Indiana. What would you suggest in that area?

Hi John. It really depends on the type of repair that you had done. If the repair consisted of sanding and body filler, then the rust was never really removed so it’s going to continue to come back. If you’re seeing bubbles in the paint, then it’s rusting from the back side which means it’s worse than it looks. At a minimum we would recommend sand/media blasting the bubbled area to see what you’re dealing with. You may be able to weld in a few spot patches and then do bodywork over that, or you may need to cut out more of the wheel arch and weld in a new arch section prior to doing the bodywork. Either way I would try to get behind the outer arch once the work is done, paint it and coat it with undercoating or a cavity wax to help seal it up. For the undercarriage, I would recommend removing as much of the rust scale as possible, clean it with something like Prepstep to remove any grease and to help neutralize the existing rust, and then coat it with a paint product like Zerorust. Zerorust was tested to withstand 2000 continuous hours of salt spray, so that will definitely help protect the undercarriage. You could also undercoat over top of the the Zerorust to provide another layer of protection. Thanks, Steve

I have a 2005 chevy Silverado that has some rust underneath carriage, I have scrapped most of it off with a steel brush and I do have a product called OVER RUST? have you heard of it?

Sorry Rick, I haven’t heard of OverRust. We have a product called PrepStep that can be diluted in water and sprayed over your vehicle’s undercarriage to help neutralize the rust. We also sell Zerorust paint that can be applied directly to a clean metal surface to help seal in any remaining rust. Thanks

Would Zerorust work well on the cab floor? Also do you have any suggestions on removing carpet pad that has been glued down to the floor?

Yes, Zerorust will work on a cab floor or any other metal surface. Just be sure to clean the surface prior to applying. Removing the carpet pad backing is tricky. I would scrape off as much as possible and then use a wax and grease remover.